|

|

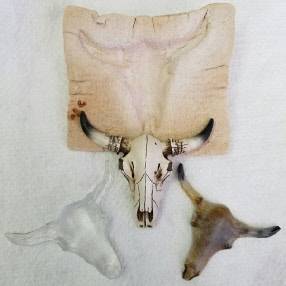

SilkeMat® is a Non-Carcinogenic refractory fiber blanket that can be cut, molded, rigidized and formed into any shape

you can make for use in a kiln to slump glass. It can be used with or without rigidizing. Although a high-grade boron

nitride separator like ZYP could be used for glass firings, it is not necessary. There is no "shot" in this product and most

firings are clean, leaving only the texture of the fiber on the glass. Since SilkeMat is a Non-Carcinogenic material,

it can be cut and handled with minimal concern. Once rigidized, the product can

even be cut or drilled to make pot molds!

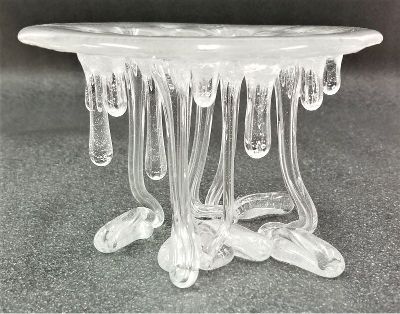

The SilkeMat Rigidizer is is NON-FLAMMABLE and formulated for molding SilkeMat sheets into rigid, reusable molds of the highest quality in performance.

Easy to use, the Rigidizer cures at 1450° F for pot melts and vitrigraph molds, and can even be used to solidify just the outer shell

of the SilkeMat mold to retain a soft, release-free interior for slumping any glass. Properly prepared and fired, all SilkeMat molds can be

reused more than once.

About 1 quart of

Rigidizer will cover 2-3 square feet of SilkeMat.

|

|

12" x 12" SilkeMat Sheet

12" x 24" SilkeMat Sheet

24" x 24" SilkeMat Sheet

|

Apply your rigidizer to the Silkemat using the yellow spreader/applicator.

Once rigid, you can use the sanding sponge to shape your SilkeMat.

|

Rigidizer Applicator/Spreader

|

|

|

|

Rigidizer is now available in powder form. Mix only what you need!

1 pound bag - makes up to 1/2 gallon of rigidizer.

Powder PDF instructions

|

1 lb Powder Rigidizer

|

5 lb Powder Rigidizer

|

|

|

|

SilkeMat Kit #1

2 sq. ft. SilkeMat

1lb. Jar Rigidizer

Sanding Sponge

Applicator

|

SilkeMat Kit #2

4 sq. ft. SilkeMat

1/2 Gallon Rigidizer

8oz Clarity Devitrification Solution

Sanding Sponge

Stirring Stick

Applicator

|

|

Clarity Devitrification Solution

Apply to fusing projects before firing to prevent devitrification on the glass surface. Fire to minimum

1350°F.

Contains no toxic or harmful chemicals. 8 oz.

Clean glass as usual. Do not stir or shake bottle before

application. Use a foam brush or sprayer to lightly coat the glass

top surface only. Do not allow the coating to migrate between or

underneath the glass. Allow to dry completely before moving the

glass to the kiln. Use water to remove he coating if necessary.

Clean applicator with water.

Temp out

|

|

|

|

|

|

|

|

|

SilkeMat Basic Instructions

SilkeMat Rigidizer Instructions

MSDS Sheet |